Iron foundry refers to the specialized industrial facility where the intricate and crucial process of cast iron manufacturing takes place. The foundry process, a cornerstone in metallurgy, involves the production of castings through intricate techniques. What is the foundry process if not a harmonious orchestration of these stages, converging to produce components that meet rigorous standards and surpass customer expectations?

The foundry process itself encompasses a range of methodologies tailored to specific requirements. What is the foundry process, then? It is the systematic approach to shaping molten metal into desired forms, making it an indispensable aspect of industrial metalworking. Casting foundry processes are vital in crafting components with intricate designs and robust structural integrity.

Let’s get to know about the foundry process in detail.

What is Foundry Process?

The foundry casting process is a multifaceted journey from molten metal to refined cast iron components. Cast iron manufacturers, well-versed in the nuances of the foundry process, utilize their expertise to create products that not only fulfill functional requirements but also showcase a level of craftsmanship that sets them apart in the industrial landscape. The foundry process, when executed with precision and care, exemplifies the seamless integration of art and engineering, yielding cast iron components that form the backbone of various industries.

The foundry process is a sophisticated sequence of operations meticulously orchestrated by cast iron manufacturers to transform raw materials into refined cast iron components. At its core, the foundry process involves a series of distinct stages, each contributing to the seamless creation of durable and precise cast iron elements.

Melting

The initiation of the foundry process begins with melting. This foundational step involves subjecting raw materials, including scrap iron and pig iron, to high temperatures in a furnace, resulting in the formation of molten metal. This molten state is crucial for the subsequent stages of the foundry process, paving the way for the transformation of iron into desired forms.

Degassing

Degassing follows melting in the iron casting process. This critical phase entails the removal of impurities and gases from the molten metal, ensuring the cast iron’s quality. The significance of this step lies in its role in refining the material, a prerequisite for achieving the desired characteristics in the final product.

Mold Making

Mold making is an intricate component of the foundry process, where skilled artisans craft molds that define the shape and features of the cast iron components. The precision involved in mold making is pivotal, as it directly influences the success of the casting foundry process. These molds serve as the blueprint for the molten metal during the subsequent pouring phase.

Pouring

Pouring is a delicate stage in the foundry process where the molten metal is carefully transferred into the prepared molds. The success of the entire casting foundry process hinges on the accuracy and finesse with which this step is executed. The molten metal takes the form of the mold, solidifying into the desired cast iron shape.

Shake Out

Post-pouring, the shakeout phase commences. During shakeout, the cast iron components are separated from the molds, demanding careful handling to avoid any damage. Subsequently, the degating stage follows, during which excess material, known as gates, is removed from the castings. This meticulous step ensures that the final cast iron components adhere to specified dimensions and quality standards.

Degating

After the pouring and shakeout phases in the foundry casting process, the components undergo degating and surface cleaning, critical steps in ensuring the quality and precision of cast iron products. Degating involves the meticulous removal of excess material, known as gates, from the castings. This step is imperative to meet specified dimensions and quality standards, contributing to the overall success of the foundry process.

Heat Treating

Heat treating, an indispensable element of the foundry process, enhances the mechanical properties of the cast iron. This controlled heating and cooling process imparts strength and durability to the components, aligning them with the desired specifications. The cast iron components then undergo surface cleaning, eliminating any residual material or imperfections and refining the product further.

Surface Cleaning

Following heat treating, the cast iron components undergo surface cleaning. This stage aims to eliminate any residual materials or imperfections on the surface of the castings, refining the final product. Surface cleaning enhances both the aesthetic appearance and functional aspects of the cast iron components, ensuring they meet the stringent standards set by cast iron manufacturers.

Finishing

The concluding phase is finishing, wherein the cast iron components undergo various treatments to achieve the desired appearance and texture. Grinding, polishing, or coating may be employed in this stage, depending on the intended application and aesthetic requirements.

What are the Types of the Foundry?

Captive Foundry

Captive foundries are integral parts of larger industrial enterprises, producing castings primarily for the parent company’s needs. These foundries focus on meeting the specific requirements of their parent organizations, ensuring a steady and tailored supply of cast iron components. The foundry process within captive foundries is geared towards supporting the internal manufacturing demands of the parent company, making it an essential part of the overall production ecosystem.

Independent Foundry

Independent foundries operate as standalone entities, offering casting services to a diverse range of customers and industries. These foundries are not tied to a particular parent company, providing flexibility in catering to external demands. Independent foundries engage in the foundry process to produce cast iron components that meet the specifications of various clients, showcasing versatility and adaptability in their operations.

Jobbing Foundry

Jobbing foundries specialize in handling diverse and custom orders, often producing low to medium volumes of specialized castings. The foundry process in jobbing foundries is characterized by its adaptability to unique and specific customer requirements. Jobbing foundries thrive on their ability to deliver customized solutions, making them ideal for projects that demand a high degree of individualization in cast iron components.

Production Foundry

Production foundries are geared towards high-volume manufacturing, emphasizing efficiency and economies of scale. These foundries are equipped to handle large quantities of standardized castings, streamlining the foundry process to ensure mass production. Production foundries often serve industries with consistent demand for specific cast iron components, optimizing their operations for volume output.

Ferrous Foundry

Ferrous foundries specialize in casting iron and steel components, utilizing metals containing iron in their compositions. The foundry process at ferrous foundries entails the manipulation of diverse steel varieties and cast iron. In sectors such as construction and automotive, where the strength and durability of iron and steel are of the utmost importance, these foundries perform an indispensable function.

Non-Ferrous Foundry

Non-ferrous foundries work with metals that do not contain iron, such as aluminum, copper, and zinc. The foundry process in non-ferrous foundries involves the casting of components using these non-iron alloys. These foundries cater to industries where the lightweight and corrosion-resistant properties of non-ferrous metals are essential, such as aerospace and electronics.

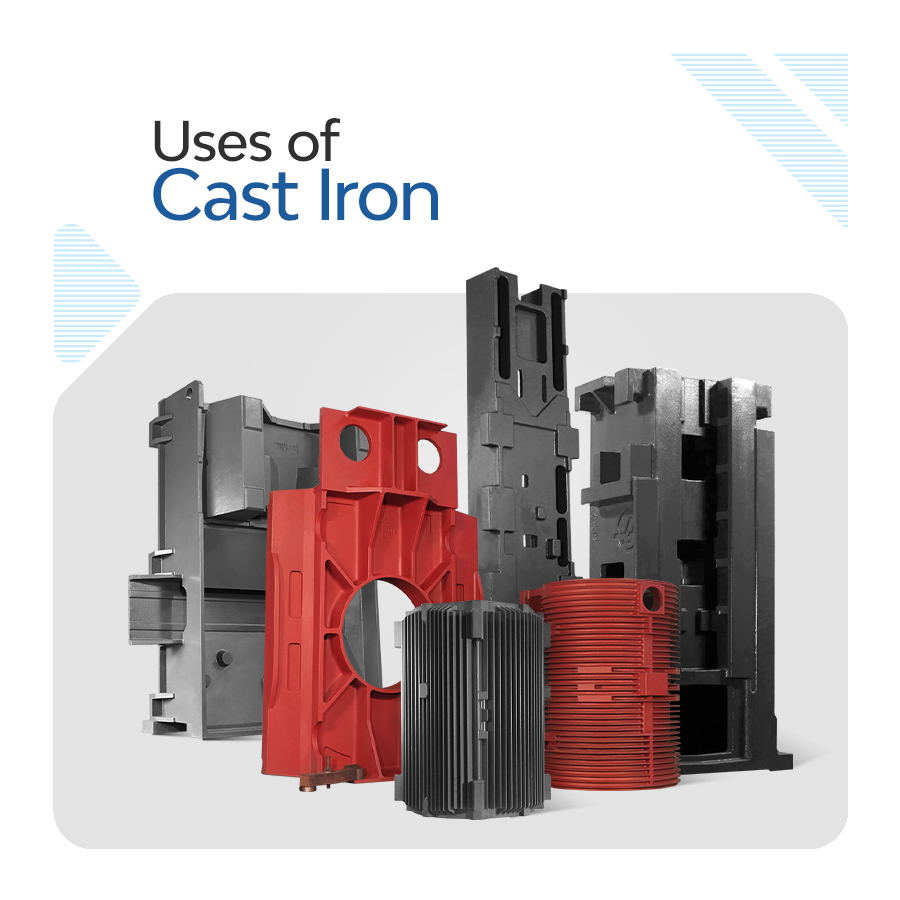

Applications of Cast Iron Foundry

Automotive Industry

Cast iron foundry products find extensive use in the automotive sector. Engine blocks, cylinder heads, and other critical components in internal combustion engines are often manufactured through the foundry process. The robustness and heat resistance of cast iron make it an ideal material for withstanding the demanding conditions within automotive engines.

Construction and Infrastructure

The construction industry relies on cast iron foundry products for a multitude of applications. Manhole covers, pipes, and drainage systems, for instance, benefit from the durability and strength of cast iron. These components endure heavy loads and harsh environmental conditions, making them integral to infrastructure projects.

Railways

Railway infrastructure utilizes cast iron foundry products for components like brake systems, rail joints, and signal equipment. The resilience of cast iron in withstanding heavy loads and providing stability makes it an ideal material for various railway applications, contributing to the safety and efficiency of rail transport systems.

Mining Industry

In the mining sector, cast iron foundry products are utilized for components like pump housings, crushers, and valves. The robust nature of cast iron makes it well-suited to handle the abrasive and demanding conditions prevalent in mining operations.

Water and Wastewater Treatment

Cast iron foundry products play a crucial role in water and wastewater treatment facilities. Pipes, valves, and fittings made through the foundry process provide durability and corrosion resistance, ensuring the efficient conveyance and management of water resources.

Energy Generation

Components used in energy generation, such as turbine housings and engine blocks for power plants, often rely on cast iron foundry products. The ability of cast iron to withstand high temperatures and pressure conditions is instrumental in ensuring the reliable operation of energy-generation equipment.

Marine Industry

Cast iron foundry products find applications in the marine sector for manufacturing components like ship engine parts, propellers, and marine pumps. The corrosion resistance and strength of cast iron make it a reliable choice for withstanding the challenging marine environment.

Oil and Gas Sector

In the oil and gas industry, cast iron foundry products are employed for components like pipe fittings, valve bodies, and pump parts. The resistance of cast iron to corrosion and its durability contribute to the longevity and reliability of equipment used in the extraction and processing of oil and gas.

Kitchen Appliances

Cast iron’s heat retention properties make it ideal for manufacturing kitchen appliances such as cookware, griddles, and skillet pans. The even distribution of heat ensures efficient cooking, making cast iron a popular choice in the culinary world.

Renewable Energy

With the growing emphasis on renewable energy sources, cast iron foundry products are used in the manufacturing of components for wind turbines and hydropower systems. The durability and reliability of cast iron contribute to the long-term performance of renewable energy infrastructure.

Conclusion

In conclusion, the foundry process stands as a cornerstone in industrial manufacturing, shaping the foundation of numerous sectors with the production of durable and versatile cast iron components. As we explore the diverse applications across automotive, construction, mining, and more, the role of cast iron manufacturers becomes apparent. Among them, Mahadev Precision Cast Pvt Ltd emerges as a notable player, with a production capacity for casting up to 3 tons.

Mahadev Precision Cast Pvt Ltd, an adept cast iron manufacturer, exemplifies the seamless integration of expertise and technology in the casting foundry process. Their commitment to precision and quality echoes the broader significance of the foundry process in meeting the varied demands of modern industries.

Answering More Questions About Iron Foundry

What is the process of foundry pattern?

The foundry pattern process involves creating a replica of the desired cast iron component. Patterns, made of wood or metal, serve as templates. These patterns guide the mold-making process, ensuring precision and accuracy in the final casting foundry process.

What are the steps in the casting process?

The foundry casting process encompasses crucial steps: pattern making, mold preparation, melting metal, pouring into the mold, cooling, and removing the casting. Skilled cast iron manufacturers navigate these steps to craft precise and durable cast iron components.

What are the benefits of casting?

Casting offers numerous benefits, including complex shape production, cost-effectiveness in mass production, and material versatility. The foundry process allows for intricate designs, precise dimensions, and the efficient production of components for diverse applications.

What is the process after casting?

Post-casting, components undergo essential processes. Heat treating enhances mechanical properties, surface cleaning removes imperfections, and finishing imparts the desired appearance. This comprehensive approach ensures that cast iron components meet stringent standards set by cast iron manufacturers.