Ever wondered if there’s a casting method that breaks the mold—literally? No Bake Casting, also known as No Bake Sand Casting, flips the script on conventional sand casting norms. But why is it turning heads? The deviation from the typical sand casting routine, waving goodbye to the time-consuming process of baking molds before metal pouring. This departure introduces an exciting spontaneity, injecting unpredictability into the age-old art of metal casting.

No bake casting brings an intriguing blend of complexity and simplicity to the table. The perplexity comes from its unconventional nature—no more waiting for molds to bake. Crafting these molds needs precision and variability, giving rise to what we like to call the “burstiness” of the process.

Let’s Understand the Basics of No Bake Casting

No Bake Casting emerges as a captivating performer, stealing the spotlight among its counterparts like cold box and heat-activated methods. The basic principle revolves around a binder and catalyst melding with sand to sculpt a mold akin to a robust brick upon curing. However, what sets No Bake Casting apart lies in the details—how the sand, resin binder, and catalyst collaborate to create a masterpiece.

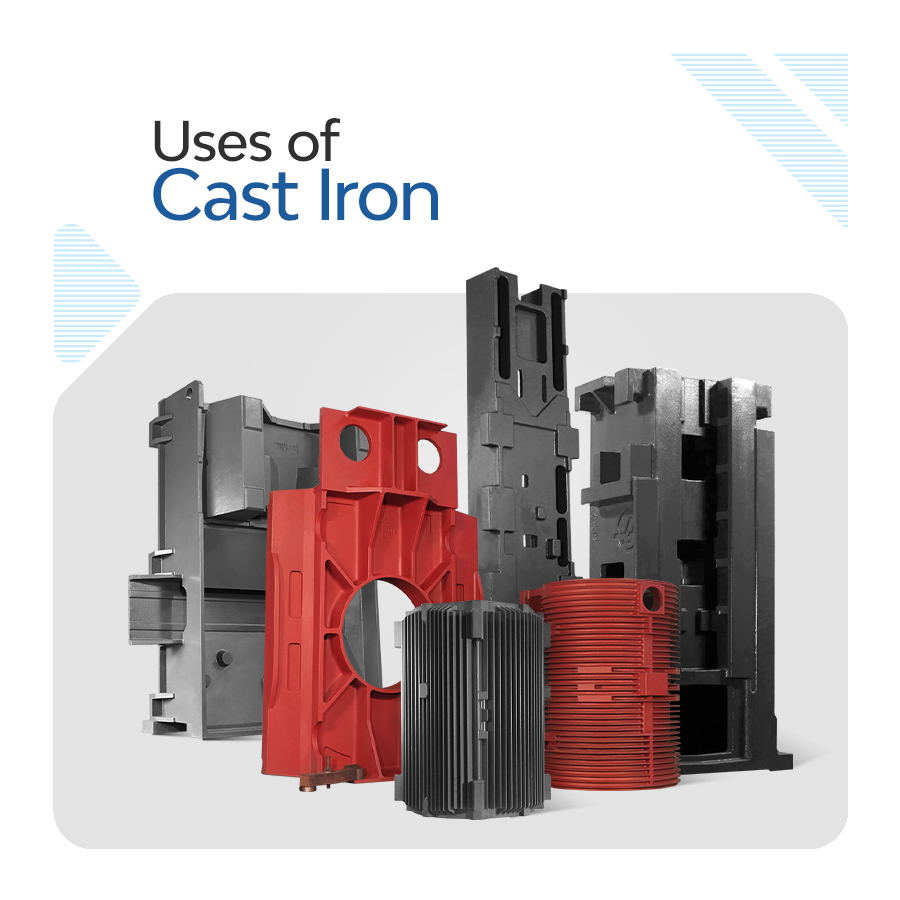

The beauty of No Bake Casting lies not only in its strength but also in its versatility. Unlike a meticulous artist working on a masterpiece, No Bake Casting caters to virtually all metals, accommodating component weights ranging from a mere pound to several hundred thousand pounds.

But what truly makes No Bake Casting a marvel is its design flexibility. The rigidity and tensile strength of no-bake molds allow for the routine production of thin sections as delicate as 0.1 inches. The twist? Minimal draft and radii requirements in casting design, offering a playground for intricate shapes and configurations that often remain elusive to other casting methods.

Not only this, you can’t overlook its reduced susceptibility to gas-related defects. The nitrogen content in most binder systems used for No Bake Casting acts as a shield, minimizing the risk of gas porosity. Castings with fine surface finishes that can be further enhanced with coatings, supporting special finishing touches like paint or dressing.

As we have a basic idea of what No Bake casting is, let’s understand the advantages it entails.

Benefits of No Bake Casting

With various advantages, No Bake casting becomes an ideal method in the modern and tech-oriented world. Let’s see what it brings to the table.

Versatility

At the heart of No Bake Sand Casting’s versatility lies its ability to cater to components of diverse weights, from the delicacy of less than a pound to the robustness of several hundred thousand pounds. This adaptability turns the spotlight on a casting method that seamlessly accommodates the intricacies of various industries, whispering the mantra that weight is no barrier to its prowess.

Cost-Effective

The benefit of No Bake Sand Casting lies not just in its mechanical precision but in its economic viability. It’s a silent architect of cost-effectiveness, crafting a narrative that challenges the notion that precision must always come at a premium. This charm draws attention to the process’s ability to achieve intricate designs without a hefty price tag.

High Strength

At the core of No Bake Sand Casting’s strength-enhancing magic lies the intricate dance between the binder and catalyst. The sand used in the cast iron process is meticulously mixed with a chemical binder and catalyst system. The synergy between these elements initiates a bonding process that, upon curing, transforms the sand mixture into a robust, brick-like mold. This binding phenomenon acts as an architectural backbone, fortifying the structure against the impending molten metal.

Lightweight

The secret to the lightweight nature of No Bake Casting lies in the carefully chosen sand resin binder. Unlike traditional casting methods, where sand molds might be laden with heavy binders, No Bake Sand Casting opts for binders that are not only effective in creating a sturdy mold but also contribute minimally to the overall density. This reduction in density ensures that the final casting carries a feather-light disposition.

No Bake Casting Process

No Bake Casting intricately weaves a narrative of complexity, precision, and unparalleled versatility. Let’s unravel the layers of this process, exploring the choreography that defines No Bake Sand Casting in all its nuanced glory.

Crafting the Mixture

The overture of No Bake Casting commences with the careful crafting of a sand mixture. Unlike conventional casting methods, this concoction involves the marriage of sand with a chemical binder and catalyst system. The synergy between these elements sparks a transformation, turning the mixture into a pliable, moldable medium for the casting that lies ahead.

The Continuous Mixing

As the mixture is made, the sophisticated machinery ensures uniformity in the distribution of the chemical binder. Each grain of sand twirls and blends to create a homogenous mixture, setting the foundation for the subsequent acts of the casting process.

Mold Formation

The sand, now imbued with the binding chemistry, wraps itself around the cope and drag halves of the tooling. The precision in this act is crucial, as the sand mixture must be given just the right amount of time to harden. The result—a solid mold with a strength resembling that of a brick—stands testament to the finesse inherent in No Bake Casting.

Curing and Solidification

Once the mold is formed, it undergoes the curing process that has no high-temperature baking. This controlled pace minimizes internal stresses, contributing to the strength and resilience of the finished mold.

The Refractory Encore

This additional layer, applied with finesse, further enhances the mold’s resilience. It becomes a shield, poised to embrace the molten metal in the subsequent act and ensuring a flawless performance in the casting of intricate shapes.

Tooling Withdrawal

At this stage, the halves of the mold are revealed. Each part of the tooling is disengaged with a precision that borders, allowing the mold to stand independently, ready for its role in the grand spectacle of metal casting.

Assembly and Pouring

This is the final stage where the mold halves come together in an assembly, creating a complete mold ready for the pouring of molten metal. No Bake Casting’s adaptability shines here, accommodating a diverse range of metals with a versatility that mirrors the complexity of the entire performance.

Types of Sand Casting

There are various types of Sand Casting. Let’s check out a few among the many.

Green Sand Casting

A foundational method in foundries, green sand casting deftly amalgamates sand, clay, water, and additives to craft molds, exhibiting unparalleled adaptability and cost-effectiveness.

Resin Sand Casting

With the infusion of resins, mold strength ascends, achieved by bonding sand particles, resulting in molds exuding durability and high-quality finishes, presenting a distinct leap in casting innovation.

Shell Mold Casting

By delicately crafting a thin shell around a pattern, this method earns distinction for precision and dimensional accuracy, positioning itself as the prime choice for intricate castings, a testament to its finesse.

Air Set Casting

Harnessing a high-speed continuous mixer, air set casting harmoniously blends sand with a binder, blown onto a pattern, setting at room temperature. This method unfolds as a versatile and efficient mold formation approach, epitomizing adaptability.

Waterglass/Sodium Silicate

Sodium silicate adds an innovative facet to sand mold casting. Essential for creating cavities, it solidifies swiftly upon exposure to carbon dioxide, a transformation that must be precisely managed. However, incorrect combinations may result in a stubborn core, complicating the casting breakdown process.

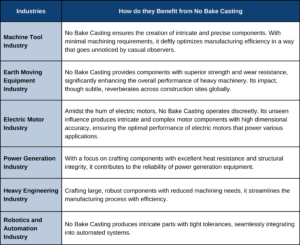

For Which Industries No Bake Casting is Suitable?

Here are the following industries that benefit with No Bake Casting process:

We are your Innovative Partner!

Mahadev Precision Pvt. Ltd. enters the picture as a silent powerhouse in this invisible world as enterprises silently prosper beneath the shadow of No Bake Casting.

Bridging the complexity of the No Bake sand casting process with ease, Mahadev Precision Pvt. Ltd. is a shining example of ingenuity. The firm, which has a 4,00,000-square-foot production factory and can produce casting weights ranging from 300 kg to 3 tonnes, is dedicated to perfection, which is evident in the way their gear runs.

As a tribute to their constant attention to quality, accuracy, and technical brilliance, Mahadev Precision Pvt. Ltd. plays a crucial part in this world where subtlety meets strength, pushing the frontiers of what’s possible in the no bake casting industry.

Know More About No Bake Casting

What is the difference between green sand and No Bake sand?

Green sand relies on sand, clay, water, and additives, while no bake sand, an avant-garde in foundry, uses a chemical binder for mold strength, redefining traditional casting with its silent revolution.

What is the no bake casting method?

No bake casting skips mold baking, employing a chemical binder to form robust molds, showcasing innovation in foundry practices, undetected yet transformative.

What is baking sand in casting?

Baking sand is the essential step in curing the mold, ensuring stability and strength, crucial in the traditional green sand casting process.

What are the two types of sand casting?

Green sand casting, rooted in tradition, contrasts with no bake sand casting, an avant-garde presence. Each contributes a unique note to metal shaping.