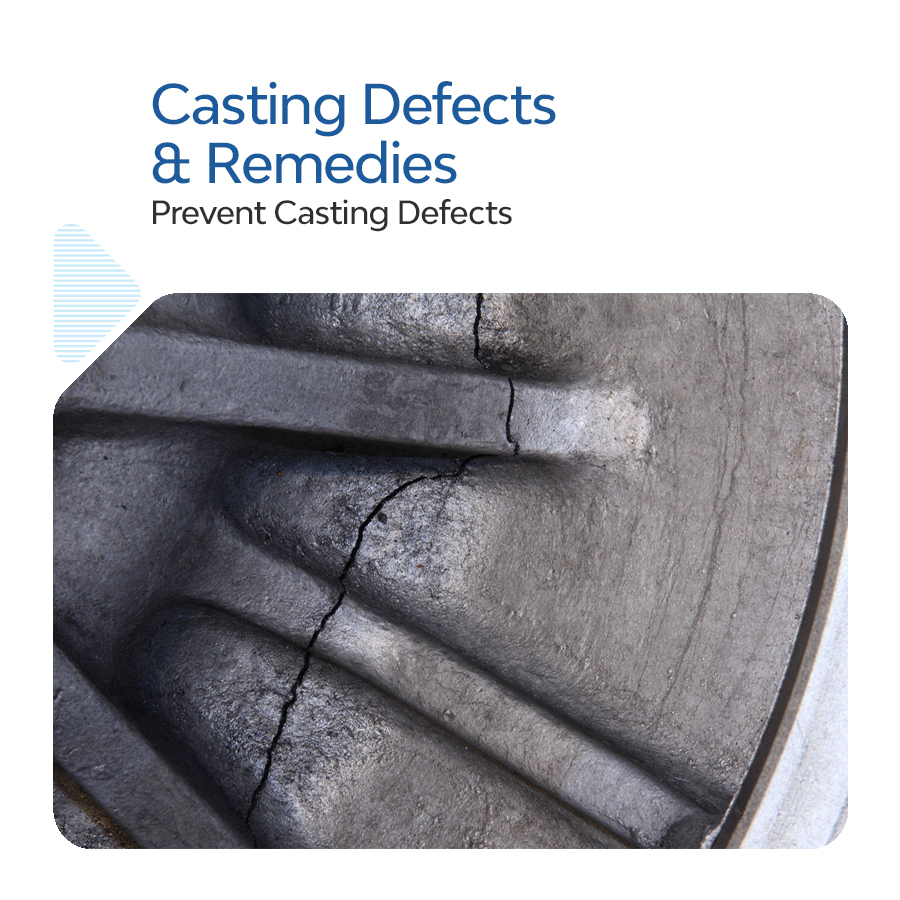

What are Casting Defects?

Metal casting is a complex procedure that requires applying tremendous pressure to molten metal, leaving it prone to a variety of undesirable events that may jeopardize the quality of the final products. These are casting defects, which are causing considerable worries among manufacturers.

Casting defects can be in a variety of kinds. Each has its unique characteristics, causes, and preventative methods. Understanding the different connected faults and reasons is essential for casting mastery. As a result, you may proactively prevent these flaws and provide high-quality items to clients.

In this post, we will understand the fundamentals of defects that may arise throughout various casting processes, as well as particular instances of problems that may show in your castings. You will also learn about the many causes of these casting faults and remedies. Knowing the most typical faults that arise throughout the metal casting process can help you know what to look out for.

What are the Types of Casting Defects?

A casting defect can compromise the product’s integrity or functioning. While certain casting defects can be overlooked, the majority must be fixed or avoided. Let’s look at the casting defects and remedies.

Pinholes

What is it?

The size of a pinhole is minuscule; we’re talking about a mere 2 millimeters here. The top portion of a mold, the cope, is often where you can find them. Little air pockets that form while casting anything can ruin its surface.

Cause

- Poor ventilation

- Moisture

- Inadequate Mold Preparation

- Gas Evolution

Remedies

- Make sure the mold is well-ventilated by reworking it or installing more vents.

- Make sure that the mold and casting materials don’t get too wet.

- Be careful to clean and coat mold surfaces properly.

- Tune casting parameters like pressure and temperature.

- To lessen the likelihood of pinholes, you may want to experiment with various mold coatings or materials.

Surface Blowhole

What is it?

Blowholes, or “blows,” are bigger cavities than pinholes. A subsurface blowhole emerges on the interior of a cast and is often not apparent until after machining.

Causes

- Air escape channels or inadequate ventilation inside the mold.

- Polluting the molten metal with gasses or moisture.

- Extreme gas evolution is caused by high pouring temperatures.

- Inadequate mold strength or poor mold compaction.

- Turbulence during filling due to an incorrectly designed gating mechanism.

Remedies

- Ensure appropriate air escape by enhancing mold venting.

- To decrease the amount of moisture, preheat the molds.

- Degassing of molten metal before pouring.

- Reduce turbulence by optimizing the pouring settings.

- Find a way to make molds that are stronger and more compact using new methods or materials.

Open Holes

What is it?

These blowholes show on the surface of the cast and are more visible than subterranean blowholes.

Causes

- The metal does not flow adequately into the mold cavity due to the incorrect gating design.

- During casting, trapped air pockets occur because of inadequate ventilation.

- Not enough metal or too much shrinkage as it solidifies.

- Castings with holes in them are the result of mold deterioration or erosion.

- Since the pouring temperature was too low, the material solidified before the mold was filled.

Remedies

- Enhance metal flow and distribution by adjusting the gating mechanism.

- Prevent trapped air pockets by improving mold venting.

- Raising the pouring temperature will prevent solidification too soon and guarantee that the mold is filled to the top.

Open Shrinkage

What is it?

These are open to the atmosphere. The shrinking cavity is air-compensated as it develops. Pipes are open shrinkage faults that appear on the surface and burrow into the casting.

Causes

- The casting does not get enough molten metal to solidify.

- The metal’s composition or the pace of cooling causes a high solidification shrinkage.

- Mold collapse or distortion due to insufficient stiffness or strength.

Remedies

- To accommodate more molten metal, you may either enlarge the feeders or add more of them.

- Modify the settings of the casting process or use chill blocks to regulate the cooling pace.

- Add more structures or materials to support the mold.

Closed Shrinkage

What is it?

When the metal cools and shrinks as it solidifies, it leaves hollow spaces within the casting—a phenomenon known as closed shrinkage.

Causes

- The feeding of shrinkage gaps is incomplete due to rapid solidification.

- A high rate of cooling or alloy composition causes solidification shrinkage.

- Entrapped gasses generate shrinkage gaps when venting is inadequate.

Remedies

- To extend the feeding period, raise the pouring temperature.

- To reduce the amount of gas trapped, use vacuum or pressure casting methods.

- To reduce internal tensions, heat the cast material after casting.

Cuts and Washes

What is it?

Erosion or metal wash-off during casting may lead to surface imperfections on castings known as cuts and washes casting defects.

Causes

- Rapid deposition of molten metal causes mold surfaces to erode.

- Surface preparation or mold coating is inadequate.

- A metal wash-off caused by turbulent metal flow.

- Molds that are too pliable cause distortion or wear.

Remedies

- Control the flow of metal by optimizing the design of the gating mechanism.

- Make sure the mold surfaces are clean and ready to cast before you begin.

- Regulate metal flow and decrease turbulence with the use of filters or gating aids.

- Refine casting settings such that metal and mold contact as little as possible.

Fusion

What is it?

An incomplete bonding, known as a fusion defect, happens when liquid metal does not fuse entirely with hardened metal.

Causes

- Rapid solidification at contact locations caused by inadequate mold preheating.

- Inadequate fusion and uneven metal flow due to poorly designed gates.

- When casting, the metal’s high viscosity prevents it from fusing properly.

- Proper fusion cannot occur because of trapped gasses caused by inadequate mold venting.

Remedies

- Reduce heat loss from molds by using insulating materials.

- Make sure the metal is filled evenly by optimizing the sizes and positions of the gates.

- Maximize the metal’s fluidity by fine-tuning casting parameters like temperature and pressure.

- Make sure the mold can let out enough gas while casting by improving its design.

Run Out

What is it?

When too much liquid metal escapes the mold before it solidifies, a condition known as run-out defect occurs. This leads to an incomplete casting.

Causes

- >If you pour too much into the mold, it will overfill the cavity.

- Mold deformation due to insufficient support or stiffness.

- A mold leak caused by a poorly sealed mold.

- Extremely fluid metal due to high temperature.

- Lack of proper ventilation leads to the buildup of gasses that interfere with the free movement of metals.

Remedies

- Set up mechanisms that pour automatically so you can regulate it precisely.

- Prevent distortion by reinforcing mold structures.

- Fix or replace worn mold parts as needed during routine maintenance.

- Adjust the cooling system so that the metal stays at the specified temperature.

- Make sure the mold can let out enough gas while casting by improving its design.

Metal Penetration

What is it?

Rough or uneven casting surfaces result from a metal penetration fault, which happens when molten metal enters the surface of the mold.

Causes

- Metal becomes too fluid due to high pouring temperature.

- The metal flow is turbulent due to the improper design of the gating mechanism.

- Metals with a high viscosity make it difficult to fill complex mold features.

Remedies

- To manage the flow of metal, lower the pouring temperature.

- Make sure the mold surfaces are clean and ready to cast before you begin.

- Evaluate and enhance gating design with the use of simulation tools.

Warping

What is it?

A casting may develop a warping fault if it twists or deforms as a result of internal tensions or uneven cooling.

Causes

- During solidification, cooling rates are not uniform.

- Metals at high temperatures have rapid thermal expansion.

- Overheating in certain areas is caused by insufficient cooling systems.

Remedies

- To reduce the severity of temperature gradients, regulate the mold’s temperature.

- Preheating molds could reduce thermal shock.

- To control temperature differentials, use cooling devices like chill blocks or baffles.

Hot Tear

What is it?

Internal tensions during solidification may induce cracks or rips in the casting, which is known as a hot tear/crack fault.

Causes

- Differential cooling rates between thick and thin sections.

- Inadequate transfer of liquid metal into parts that are cooling down.

- Extreme heat strains are caused by metals at high temperatures.

- Deformation caused by molds with insufficient stiffness.

- Mold with inadequate ventilation may lead to gas traps.

Remedies

- Use methods for directed solidification.

- To guarantee complete filling, modify the pouring settings.

- To reduce thermal gradients, lower the pouring temperature.

- When casting, be sure to use the correct handling and support procedures.

- Ensure that trapped gasses can escape via improving mold venting.

Mahadev Precision: Decoding Casting Defects with Expertise

In order to achieve high-quality castings, it is essential to pay close attention to detail and have knowledge, as we have explored the casting defects and remedies. We take great satisfaction at our casting foundry in our ability to foresee and resolve these problems. Our advanced foundry can cast up to three tons of iron, so you can be sure that every project will be done to the highest standard of quality. When it comes to casting, you can rely on Mahadev Precision Pvt. Ltd. Our team has the experience and resources to handle any job.

Explore More About Casting Defects

What is casting, and what are its defects?

Casting defects are undesirable abnormalities in the metal casting production process. Surface flaws, inclusion faults, molding and pouring defects, and cooling defects are some of the many forms of defects. Some casting faults, such as an extremely rough surface, are apparent to the naked eye.

What are the remedies for Casting Defects?

There are remedies for every casting defect. Here are a few:

- Proper ramming with great strength is required.

- Molten metal should be adequately fluxed so that impurities can be readily removed before flowing into molds.

- Proper strengthening of the cope’s sand projections.

What if there is a casting mistake on your end?

We always aim to make sure that our customers are happy first. Since we have a solid procedure to deal with and fix the issue, casting defects are very uncommon on our end. Together, we can identify the source of the issue and put a plan in motion to fix it quickly. Our utmost priority is to guarantee that you acquire the top-notch castings that you expect from Mahadev Precision. Therefore, our solutions may include re-casting, repairs, or offering alternative alternatives.

Read More: